Rare earth metals are not as rare as their name suggests. However, they are indispensable for the modern economy. After all, these 17 metals are essential raw materials for digitalisation and the energy transition. They are found in smartphones, computers, screens and batteries – without them, no electric motor would run and no wind turbine would turn. Because Europe is almost entirely dependent on imports from China, these raw materials are considered to be critical.

However, rare earth metals are also critical because of their extraction. They always occur in compound form in natural ores – but as these elements are chemically very similar, they are difficult to separate. Traditional separation processes are therefore very chemical- and energy-intensive and require several extraction steps. This makes the extraction and purification of these metals expensive, resource- and time-consuming and extremely harmful to the environment.

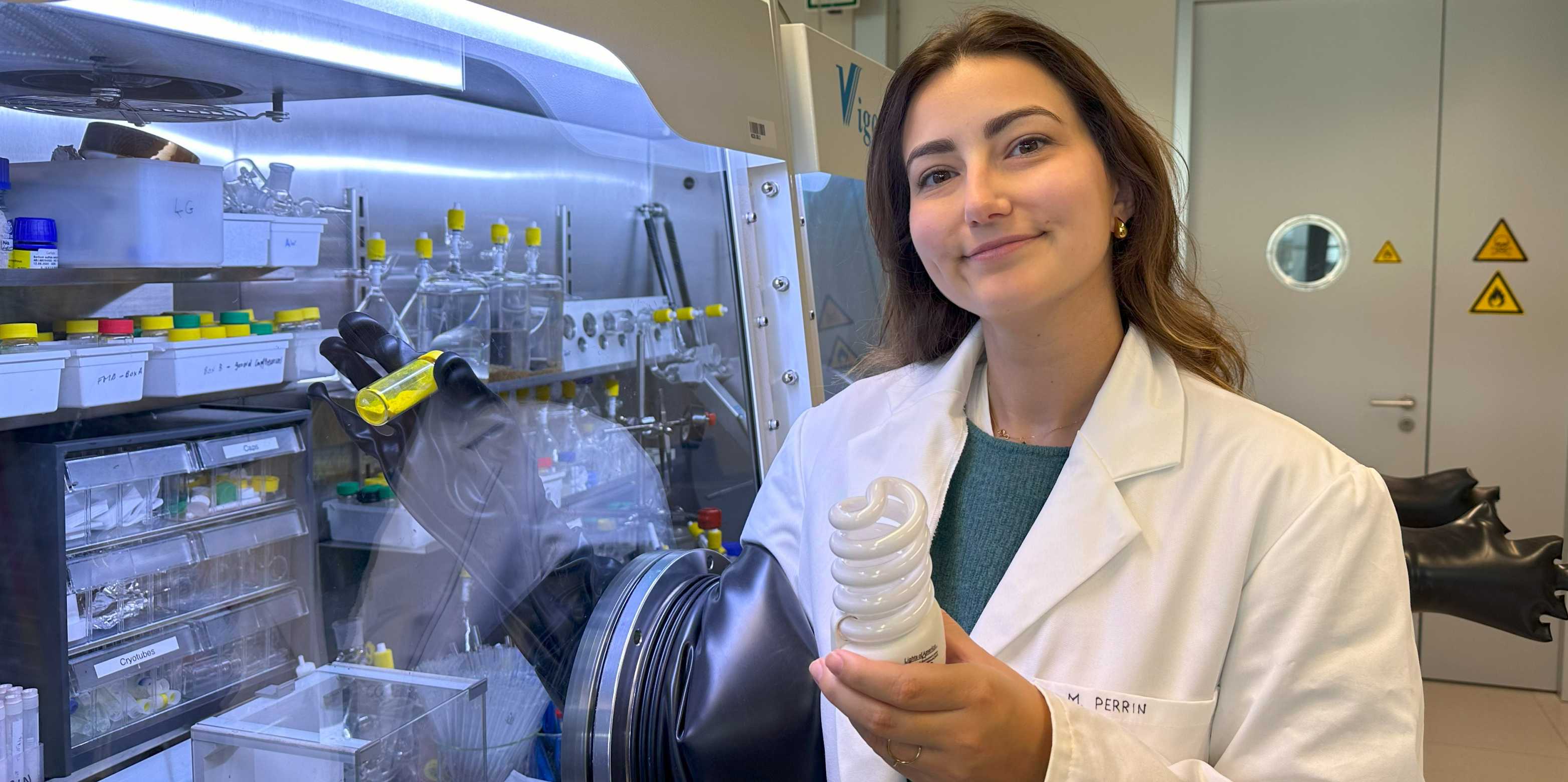

“Rare earth metals are hardly ever recycled in Europe,” says Victor Mougel, Professor at the Laboratory of Inorganic Chemistry at ETH Zurich. A team of researchers led by Mougel wants to change this. “There is an urgent need for sustainable and uncomplicated methods for separating and recovering these strategic raw materials from various sources,” says the chemist.

In a study recently published in the journal external pageNature Communications, the team presents a surprisingly simple method for efficiently separating and recovering the rare earth metal europium from complex mixtures including other rare earth metals.

Inspired by nature

Marie Perrin, a doctoral student in Mougel’s group and first author of the study, explains: “Existing separation methods are based on hundreds of liquid-liquid extraction steps and are inefficient – the recycling of europium has so far been impractical.” In their study, they show how a simple inorganic reagent can significantly improve separation. “This allows us to obtain europium in a few simple steps – and in quantities that are at least 50 times higher than with previous separation methods,” says Perrin.

The key to this technique can be found in small inorganic molecules featuring four sulphur atoms around tungsten or molybdenum: tetrathiometallates. The researchers were inspired by the world of proteins. Tetrathiometallates are found as a binding site for metals in natural enzymes and are used as active substances against cancer and copper metabolism disorders.

For the first time, tetrathiometallates are now also being used as ligands for the separation of rare earth metals. Their unique redox properties come into play here, reducing europium to its unusual divalent state and thus simplifying separation from the other trivalent rare earth metals.