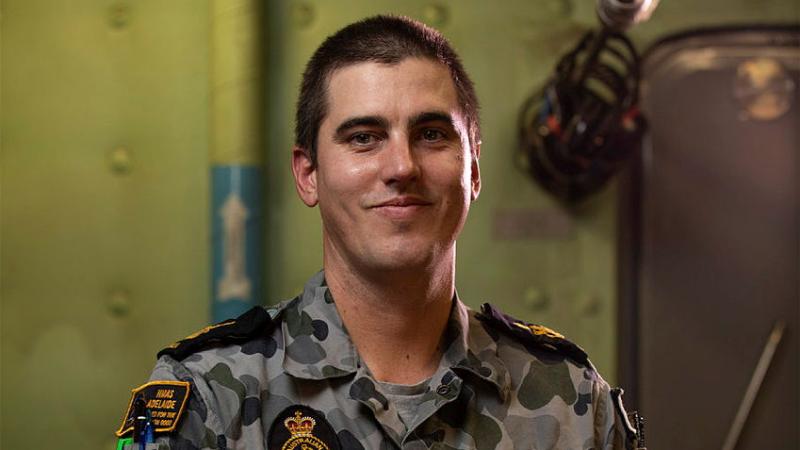

After seeing skill gaps in apprentices’ welding techniques, Petty Officer Jim Schacht developed projects that sped up their qualification completion time by 40 per cent.

These covered on-the-job brazing and forming, TIG, MIG and ARC welding practices.

The projects are now recognised as Navy’s fabrication on-the-job training, allowing for trade completion.

Petty Officer Schacht said skilled fabricators were essential to meet the high-quality demands throughout the fleet.

“At one stage at Fleet Support Unit – South East we had more untrained sailors in fabrication than trained,” he said.

“There was nothing in place to address the skill gaps effectively, so we developed our own solutions.

“We needed to prioritise skill development, and this allowed us to target specific competencies.”

Petty Officer Schacht and his team received a small amount of internal funding to start the project to prove they could qualify sailors.

When the projects were found to be effective, the training authority provided ongoing funding.

“The feedback from the training authority was overwhelmingly positive,” Petty Officer Schacht said.

The projects were designed to be small, yet complex enough to engage apprentices while minimising resources.

“We had to make sure our projects were small and held the attention of the young apprentices,” he said.

The support allowed them to scale up their efforts and expand the program, offering training and development to the entire east-coast fleet.

For this work, Petty Officer Schacht received the Conspicuous Service Medal as part of the King’s Birthday Honours.

“I just feel honoured and really grateful for the support in the development stages all the way through to the final product,” he said.

Petty Officer Schacht also paid tribute to Able Seaman Seamus Rogers who helped develop the projects and prototypes.

“I absolutely appreciate all the support that I’ve received from the engineering sector, from supervisors and the great engineering network,” Petty Officer Schacht said.