Researchers from the University of Cambridge say they have developed a groundbreaking method to create lightweight and eco-friendly sensors that can be “directly and imperceptibly” printed onto a variety of biological surfaces, from human skin to flower petals.

Taking inspiration from spider silk, the Cambridge researchers incorporated biocompatible conducting polymer PEDOT:PSS, hyaluronic acid, and polyethylene oxide into their bioelectronic fibers which were produced from a water-based solution using an orbital spinning method.

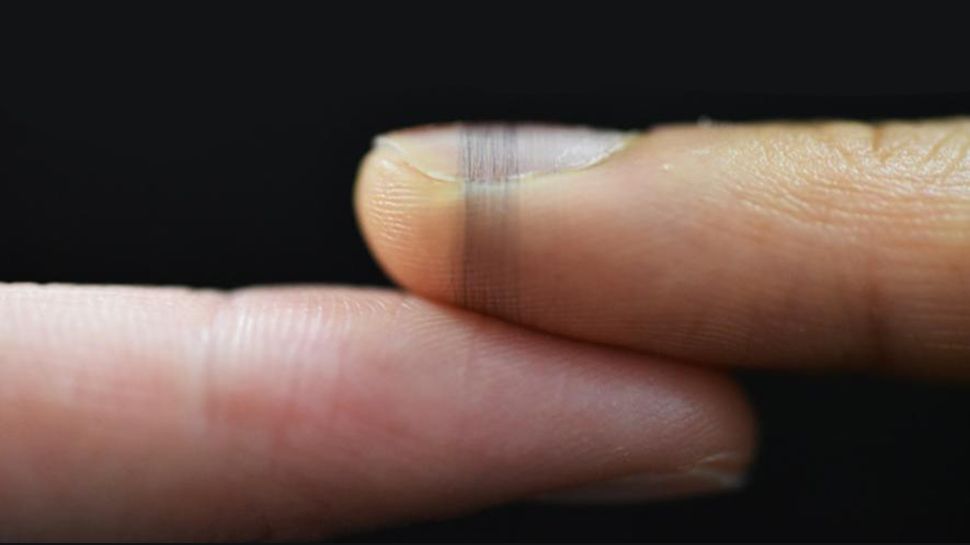

The fibers, which are at least 50 times smaller than a human hair, are so lightweight that they can be printed directly onto delicate surfaces like the fluffy seedhead of a dandelion without damaging their structures. When printed on skin, the fiber sensors conform to the epidermis and expose the sweat pores, allowing for seamless integration without causing discomfort. Initial tests on human fingers suggest that these sensors could be used for continuous health monitoring.

Sensors almost anywhere

“If you want to accurately sense anything on a biological surface like skin or a leaf, the interface between the device and the surface is vital,” said Professor Yan Yan Shery Huang from Cambridge’s Department of Engineering, who led the research. “We also want bioelectronics that are completely imperceptible to the user, so they don’t in any way interfere with how the user interacts with the world, and we want them to be sustainable and low waste.”

This proposed method for augmenting living structures has the potential for a wide range of applications. It could revolutionize healthcare, electronic textiles, and environmental monitoring. By printing sensors directly onto the skin, for example, continuous health monitoring could become more accurate and non-intrusive. Additionally, it could improve the sensory experience in VR applications.

“Using our simple fabrication technique, we can put sensors almost anywhere and repair them where and when they need it, without needing a big printing machine or a centralized manufacturing facility,” said Huang. “These sensors can be made on-demand, right where they’re needed, and produce minimal waste and emissions.”

In addition to being lightweight and eco-friendly, these bioelectronic fibers can simply be washed away when they reach the end of their useful lifespan.

The research was published in Nature Electronics as ‘Sustainable and imperceptible augmentation of living structures with organic bioelectronic fibers’.